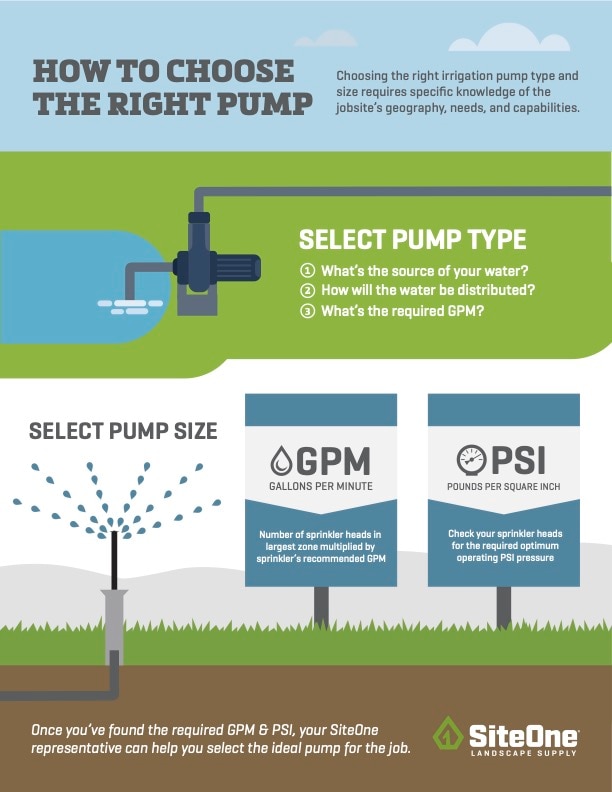

A successful landscape project starts with choosing the right equipment for the job, and a key category of equipment are the irrigation pumps you’ll be using.

The choice of that pump will depend on a host of factors, including how many GPM (gallons per minute) the proposed system requires, the source of your water, and how that water will be distributed.

Check out the array of pumps available on SiteOne here.

Three Pump Types

The three primary types of pumps you’ll encounter for landscaping needs are centrifugal, jet and submersible. Technically, the last two are forms of centrifugal pumps, but each have special applications. Let’s take a closer look at each:

- Centrifugal Pumps: A centrifugal pump uses rotation to add velocity to water and then converts that velocity into flow. Centrifugal pumps are the ideal choice when pumping water from lakes, streams, reservoirs or shallow wells. In order to operate, centrifugal pumps need to be “primed” first – i.e., filled completely with water.

- Jet Pumps: Yet another type of centrifugal pump, a jet pump uses the Venturi effect (i.e., when fluid pressure drops as that fluid flows through a constricted section of a pipe) to create suction and draw fluid into a pipe. Its driving nozzle transforms the fluid pressure into a high-speed jet.

Jet pumps are commonly used in low-flow irrigation applications, are popular in warm climates and where water tables are high, and can be installed in shallow or deep wells.

- Submersible Pumps: A submersible pump is a turbine pump attached to a submersible electric motor. By definition, both the pump and the motor are suspended in the water, and because the pump is positioned above the motor, the water enters the pump by way of a screen between the pump and the motor.

What’s Your GPM?

In order to choose the ideal irrigation pump size, you need to know the GPM (gallons per minute) required by the largest zone of your irrigation system. You determine GPM by multiplying the number of sprinkler heads in that largest zone by the GPM that the sprinkler manufacturer specifies for maximum efficiency.

Secondly, check your sprinkler heads and note the optimum operating pressure those heads require—the PSI (pounds per square inch). Both factors—GPM and PSI—will determine the pump size. With these two figures in hand, your SiteOne representative can then help you select the ideal pump for the job.

Where’s Your Power?

The pump you select will need to run efficiently off the power available on site. Does your pump location have 110v or 220v power? Knowing this information will also help your SiteOne rep determine the best pump for the job.

Where’s Your Water?

Knowing your irrigation pump water source will also determine the ideal pump. Some possible scenarios to consider:

City Water: Are you using tapping into city water? City-water sources (or gravity-fed systems) typically have some incoming pressure, which your pump will then boost up to the correct pressure.

Lake Water: Are you pumping from a lake, pond or stream? If so, how far away is that source? If it’s a significant distance away, you may need longer pipes, which will likely require higher pump output to compensate for friction losses (i.e., the energy and pressure loss—because of friction—when water flows through pipes).

Dirty Water: Is the water dirty or filled with debris? Adding filtration may be necessary to prevent pump damage, but doing so may also mean additional friction losses, which will need to be offset by increased pump pressure.

Pump Control Boxes

A pump control box is essentially the “brain” of a pumping system, and does a variety of jobs that keep the system operating properly. A control box monitors the flow of water through the pump to make sure it’s at the right level. Additionally, they keep pumps from short-circuiting or overloading.

Your Pump Control Box’s Job

Knowing the primary function of the control box in your irrigation system will help you determine what you need. Ask these questions:

- Is the set-up of your irrigation system simple—requiring just one pump with one controller? Or, does it require multiple controllers and/or multiple pumps?

- Are you managing dual water sources (i.e., tank/cistern water), and switching to a city source when dry?

- Should your pump be triggered to operate based on the lake or pond level?

- Is the system conventional 24-volt or is it a 2-wire decoder system?

Pump Start Relays

An integral part of a pump-control box is the pump start relay, an electrical device that allows your irrigation timer to communicate with the pump by way of a variety of start/stop signal devices. Those devices will determine the type of pump control you need.

Pump start relays need to be installed at least 15 feet from the timer and pump to avoid electrical interference that can cause malfunctions.

Talk to your SiteOne representative about how the irrigation system will be configured (i.e., lawn controllers, system-pressure monitors, flow switching, etc.) to determine the optimal pump start relay for the job.

Required Pump Voltage & Amps

Guidelines: Standard relay contactors provide 110v to 220v for pumps ranging from ¾ to 3hp pumps. For pumps larger than 3hp, a different contactor and overload protection may be required.

Got Pump Protection?

If a pump runs dry or overheats, and there’s no mechanism in your pump control for sensing these conditions, you can easily damage the irrigation system. Adding protection features to your pump control system will prevent potential pump damage or failure.

The Munro SmartBox (available through SiteOne) delivers both the start/stop function and the system protection you need. The SmartBox has sensors that monitor pressure and temperature, and if one of those sensors indicates a problem, power is cut off to the pump, protecting it from damage.

Preventing “Backflow”

Backflow is when non-potable water or other substances flow into the piping of a public water system or a homeowner’s potable water system. Backflow happens when downstream pressure is greater than the potable-water-supply pressure—which can drop during water-line flushing, firefighting or water-main breaks.

By installing approved backflow preventers—which provide a physical barrier to prevent backflow—you keep weed killers and fertilizers from potentially entering a home’s drinking water.

SiteOne Can Help

Check out the array of pumps available on SiteOne here. Have questions about irrigation pumps and which one is ideal for your specific job? Need supplies for the job? Associates are waiting to answer your questions in your local SiteOne branch. On the jobsite? Order everything you need from the SiteOne mobile app.